Bottom price Round Bottle Screen Printing Machine - US200S2,4,6 2,4,6 color CNC Auto-Screen printer – PSI

Bottom price Round Bottle Screen Printing Machine - US200S2,4,6 2,4,6 color CNC Auto-Screen printer – PSI Detail:

Application

square/oval/cylindrical products, with or without registration point. Bottles, etc

General Description

1.Automatic loading with conveyor and robot.

Automatic flame treatment for bottles

Auto pre-registration when there is registration notch or cut threads

2. Servo motor driven shuttle, products stop any position.

3. Servo driven printing system with linear rails and bolts screw. Printing head left/right, parts up/down, parts rotation all driven by servo motor, with all parameters setting in touch screen without any tools.

4. Quick and easy change over from one product to another: 1 jig only, all other parameters will be set in touch screen.

5. Auto high efficiency electrode UV system. UV system left/right driven by servo

6. PLC control & Proface touch screen operation system.

7. Safety operation with CE standard

8. Auto printing head locking system for better printing quality.

9. Automatic unloading.

10. 1 operator only

11. All Mitsubishi servo motors, Mitsubishi PLC

Tech-Data

| Parameter Item | US300S2 | US200S4 | US200S6 | ||

| Power | 380VAC 3Phases 50/60Hz | ||||

| Air consumption | 5-7 bars | ||||

| Max printing speed | 8-10pcs/min | 3-5pcs/min | 2-3 pcs/min | ||

| Printing Diameter | 20–80mm | ||||

| Printing height | 150mm | ||||

| Printing stroke left/right | 260mm | 200mm | 200mm | ||

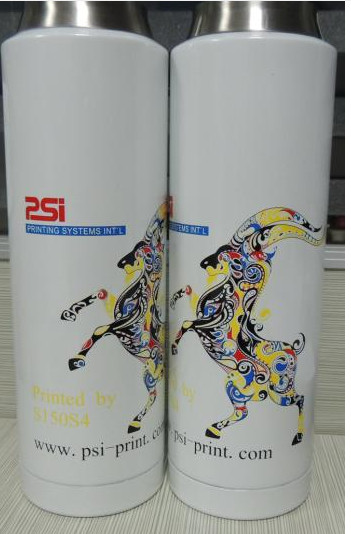

Samples

Product detail pictures:

Related Product Guide:

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for Bottom price Round Bottle Screen Printing Machine - US200S2,4,6 2,4,6 color CNC Auto-Screen printer – PSI , The product will supply to all over the world, such as: Australia, Buenos Aires, Poland, We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.